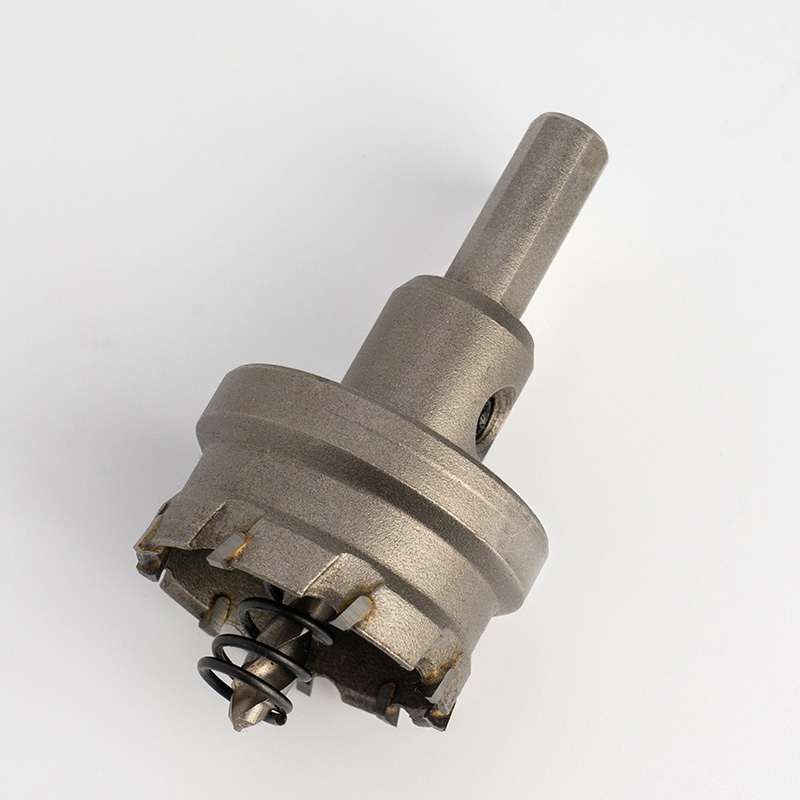

Alloy Hole Opener Type L

The company has professional tool design capabilities, relying on professional manufacturing and processing equipment, and a sound quality control system to manufacture efficient and durable hole saw products. The products have been sold at home and abroad, and are widely used in decoration, bridge and railway construction projects. .

- Commodity name: Alloy Hole Opener Type L

- Product Description

-

The characteristics of alloy hole opener

The alloy hole opener is a cutting tool specially designed for drilling and has the following features:

1. Three-plate blade design: alloy hole opener is a three-plate blade structure composed of outer edge, middle edge and inner edge. Each blade only bears 1/3 of the workload in the cutting process.

2. The inside also has a cutting edge: the inside of each blade also has a cutting edge, making the alloy hole cutter in cutting more efficient, can quickly eliminate chips, improve drilling efficiency.

3. Excellent performance: the edge of the alloy hole opener is sharp and the wear resistance is good. Because it is made of high hardness alloy steel, it can better cope with a variety of complex cutting environment and ensure the quality of drilling.

4. Smooth chip discharge: Due to the characteristics of each blade bearing part of the cutting work, the chip discharge is very smooth, not stuck, improve the drilling efficiency.

5. Easy to operate: The alloy hole opener is very simple to operate and can be used by simply inserting it into the drill, making it a great cutting tool for DIY enthusiasts.

Methods of using alloy hole openers

When using an alloy hole opener, note the following:

1. Choose the right electric drill: Because the alloy hole opener is a rotary cutting tool, it needs to be used with the electric drill. It is recommended to choose the electric drill with a power greater than 500W.

2. Select the right aperture: alloy hole cutters can drill a large range of holes, usually from 1mm to 100mm can be drilled, so it is necessary to choose the right aperture according to the actual needs.

3. Mark: Before using an alloy hole opener to drill a hole, mark the hole position to ensure the accuracy of the hole.

4. Appropriate addition of water: in the drilling process, it is necessary to add appropriate water to cool down, but also to reduce the difficulty of debris removal, improve drilling efficiency.

5. Press with light force: Press with light force when drilling. Do not apply excessive force to avoid damage to the blade.

All in all, the alloy hole opener is an excellent, easy to operate cutting tool, ideal for DIY enthusiasts, and is widely used in a variety of drilling situations.

Key words:

Get A Quote

Contact Info

Address: West of Zhenqing Village, Zhongtang, Dagang, Binhai New Area, Tianjin

Tel: +8613803097485

Email: wangwei640402@163.com